Author(s): Jon Are Beukes; Anh Hoang Dam; Kaja Skålnes Knudsen ![]()

DOI: 10.14339/STO-J-02-04 | ISSN: TBD

Combining graphene with bulk materials holds great promise for advancing and developing both civilian and defence technologies

Citation:

ABSTRACT

Combining graphene with bulk materials holds great promise for advancing and developing both civilian and defence technologies. Here, we present a large-scale Plasma Enhanced Chemical Vapour Deposition, PECVD, reactor system, FORZA, that has been developed exclusively for the production of high-quality graphene flakes and coatings. The reactor system is the largest known system of its kind, and can coat large surfaces, up to 86 cm width and 390 cm length, with vertically oriented graphene. FORZA is capable of large-area graphene coating directly on materials and devices and the graphene may be harvested continuously as a powder. FORZA graphene has been incorporated into various materials and products. It has been used to improve electric conductivity of polymers (epoxy). Further, it has been used to enhance mechanical properties of polymer material (poly lactic acid), fibre reinforced polymer composite (glass fibre/polyester) and elastomers. FORZA graphene has been used to improve ballistic performance of polymer composite material (glass fibre/polyvinyl ester) for vehicles and body armour. In addition, it is possible to coat surfaces directly with FORZA graphene on various materials (such as knife edges, carbon fibre, aluminium and copper foils) for multiple property enhancements. Graphene’s possibilities for boosting battery charging performances has also been demonstrated.

1.0 Introduction

Although the potential of graphene has been highlighted in numerous laboratory studies, there are still challenges in producing graphene with sufficient quality and scale necessary for industrial applications. The FORZA system is used both as a research reactor for determining optimum parameters for new specialized coating machines, as well as serving as a graphene machine for large scale production. Commercial and defence applications of graphene-based materials are numerous. As an example, these materials may be used as anti-corrosion and anti-icing coatings for helicopter rotor blades [1],[2],[3]. As an additive, flake graphene imparts high strength to weight ratio and can contribute enhanced mechanical, thermal, and electrical properties to polymers even at very low concentrations. As a continuous thin film or coating, graphene can be applied to a wide range of materials, providing a flexible, transparent, electrically conductive, corrosion-resistant, gas-impenetrable, and atomically thin diffusion barrier. Moreover, graphene-based materials are believed to provide high strength-to-weight ballistic solutions for vehicles and body armour. There are also significant possibilities for the enhancement of battery energy density and charge rate performance with the use of graphene.

Current methods for producing flake graphene are based on top-down exfoliation of graphite by either mechanical or chemical means [4]. Techniques, such as the Scotch-tape method [5] or shear-force mixing, can produce high-quality graphene flakes with little contamination, but are limited to small production volumes. Chemical exfoliation and chemical synthesis can produce higher volumes of graphene than mechanical exfoliation, but the process is harsh and results in substantial damage and undesirable effects on the graphene itself including defects, oxide functionalities, substitutional nitrogen, and residual metallic contaminants. Chemical waste is also an issue with chemical exfoliation [6].

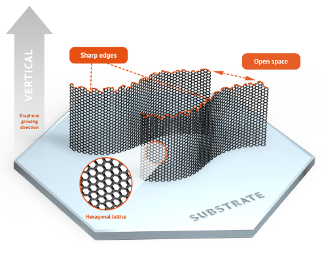

High-quality graphene films can be produced by chemical vapor deposition (CVD) [7]. CVD of graphene is a bottom-up process whereby gaseous hydrocarbons are converted to crystalline graphene via high temperatures and catalytic substrates. Although thermal CVD can produce high-quality graphene films, the trade-offs include the need for high temperatures, ~1000 °C, slow growth times, and a limited number of substrates on which is can be applied. Plasma Enhanced CVD (PECVD) is a variant of thermal CVD wherein reactive growth species are generated within a plasma environment rather than with high temperatures [8]. The advantages of PECVD include lower growth temperature, faster deposition, improved film quality, and the ability to deposit multilayer films. The high growth rates of PECVD allow graphene to be grown perpendicularly (See Figure 1) to the substrate as opposed to regular CVD processing that only deposits parallel layers. This makes it possible to grow substantially more graphene per growth area, which can easily be harvested to be used as flakes. However, a challenge with PECVD has been scaling the process to industrially relevant size.

The reactor system, FORZA, is based on a scalable microwave plasma technology platform. The system can transform carbon containing gases and hydrogen and continuously deposit vertical 3D graphene areas of up to 6.7 m2. Large-area graphene deposition has been demonstrated on a variety of substrates, including stainless steel, Inconel, aluminium, quartz, and copper, as well as more complicated structures, including metal mesh, carbon fibre cloth, and particles. Deposition can occur below 400 °C, which allows for coating of temperature sensitive materials and electronic devices. As will be shown, characterization of FORZA flake graphene with scanning electron microscopy (SEM), transmission electron microscopy (TEM), and Raman spectroscopy maps reveal excellent uniformity and high crystallinity. Properties of the graphene can further be controlled by changing the growth conditions by varying the growth time, gas compositions, input energy, pressure, and temperatures.

In this paper, we briefly describe the FORZA machine and address ways of using graphene for improving various material properties for practical applications.

Figure 1: 3D Graphene is growing perpendicularly from a substrate

2.0 Methodology

2.1 High volume production of graphene

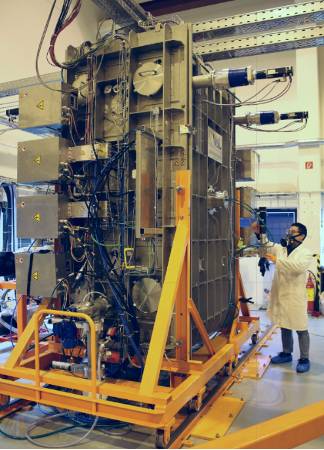

The FORZA machine (see Figure 2) was constructed as a factor 6700 scale-up of the environment from a patented laboratory device set-up with a 1cm2 growth area [9]. The corresponding growth areas in the FORZA machine consists of two 3.9 meter long metal bands where graphene can be perpendicularly deposited either by dynamically moving the belts, or by stepwise-static mode (see Figure 3 ). In this way it is possible to grow perpendicular graphene with different base length for the graphene sheets, which depending on residence time in the plasma zones, has been observed from a few hundred nm up to 30 µm thickness.

The graphene deposited on the metal bands can be harvested by mechanical scraping and conveying from the reactor. In addition to controlling the flake sizes, the morphology of the produced graphene can be controlled by varying the process parameters, such as temperatures, total gas pressure, plasma energy, gas compositions, and argon dilution parameters. For on-line analysis, the machine has a probe installed for in-situ Raman spectroscopy measurements. Further, routine characterisation of harvested graphene powder is done by Raman mapping.

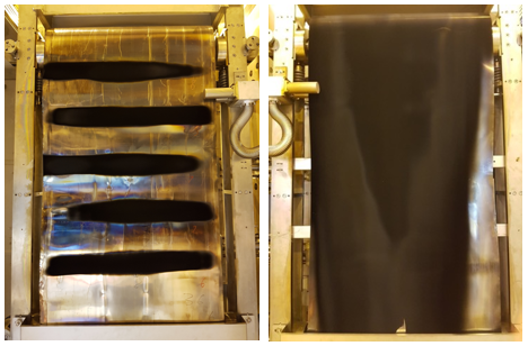

Figure 2: The FORZA graphene PECVD production unit at Cealtech, Stavanger, Norway. Inside the large vacuum chamber there are two motorized metal belts used as substrates for graphene growth. The chamber is equipped with gas reactant controls, microwave plasma generators, a harvesting system and interlock controls

Figure 3: The graphene (black substance) inside the FORZA machine can be produced using various processing parameters. Here is shown a step-mode growth (left) where the belt is kept in a static position, and a dynamic mode growth by moving the substrate at a continuous speed (right). In addition, one can tune the gas composition and temperatures in the FORZA, to produce the desired amounts and graphene qualities and morphologies

2.2 Methods for graphene characterization and mechanical testing of composite materials

As part of normal quality control routines, every batch of FORZA graphene is analysed by means of Raman spectroscopy (Raman). Other techniques such as scanning electron microscopy (SEM), transmission electron microscopy (TEM), and energy dispersive X-ray spectroscopy (EDS) are complementary used to ensure the consistency of the product.

Raman spectroscopy (Renishaw inVia, UK) is a preferred tool for characterizing graphene in-situ and as harvested from the production process, as well as during subsequent manipulation for interfacing it in various application matrices. The Raman spectra and analysis give a good indication of the crystallinity and quality and the interaction with host materials.

The morphology and nanostructure of graphene are observed by SEM (Gemini SUPRA 35VP (ZEISS), Germany) and TEM (JEOL-2100 (LaB6 filament) equipped with energy dispersive X-ray spectroscopy (EDS), operating at 200 kV, Japan). Elemental composition and impurity in graphene is identified by EDS. In addition, the TEM provides electron diffraction patterns that give valuable insight into the crystallinity of the honeycomb graphene lattice. The dispersion of graphene in a polymer/elastomer matrix is determined by X-ray diffraction (Bruker's X-ray Diffraction D8).

Tensile strengths of graphene enhanced polymer composites were measured according to the ASTM D3039 standard. Flexural strength (3-points flexure) was measured according to ISO standard 14125. All tests were performed on an Instron Applications Laboratory Model 5985. For each sample, 7 specimens were tested to reduce uncertainty on the measurement.

3.0 Results and discussion

3.1 Properties of FORZA graphene

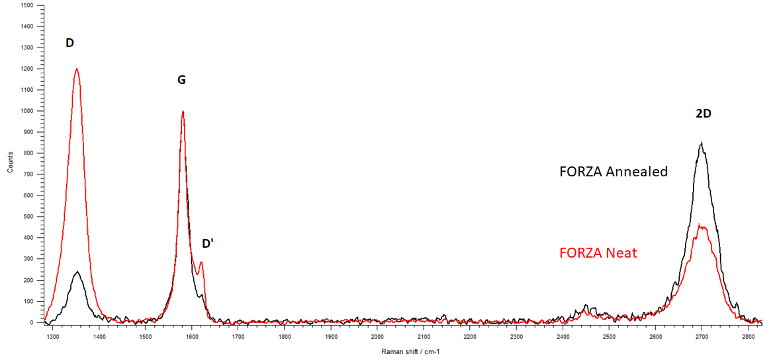

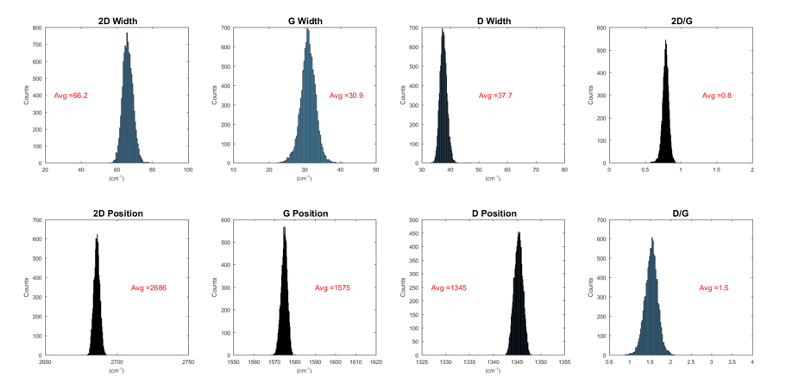

The Raman spectra of neat FORZA graphene, Figure 4, and subsequent analysis, see Figure 5 , shows that the graphene produced is very uniform. Furthermore, the neat graphene has a signature suggesting it is functionalized, which is believed to be partially hydrogenated graphene[10].

Figure 4 shows the spectrum before and after annealing the neat graphene in vacuum, and the resulting Raman spectrum looks more like pristine graphene. The neat FORZA graphene goes through some changes, where the most noteworthy is: low total mass losses of <28% as shown by thermal gravimetric analysis (TGA). A significant reduction of D and D’ peaks indicate reduction of defects (morphology and/or functionalization). The G peak width is maintained and indicates no deterioration of crystallinity. The significant increase in the 2D peak area, and the 2D/G ratio, as well as a narrower 2D peak width from 78 to 61 cm-1, indicates a reduction of over-all number of layers down to very few layers during the annealing process.

The drastic decrease in D peak in Raman by annealing is correlated to two aspects; the reduction of poor quality graphene content such as graphene with more holes and lower crystallinity, which is mechanically weaker and less thermally stable, and carbon content which is non-graphene such as amorphous carbon or other forms of carbon. This could also contribute to most of the weight loss during thermal process as is found by TGA analysis. Annealing may also reduce hydrogen that is incorporated during PECVD production of graphene in the presence of hydrogen gas. The removal of hydrogen enables the transformation of sp3 to sp2 states in atoms within the partially hydrogenated graphene. This would enhance electron mobility in the graphene sheet, and therefore an increased electrical conductivity. However, it is challenging to quantify the effect of these two effects. Which one of these two plays the most important role in improving graphene quality as seen by Raman, remains to be determined.

Figure 4: Raman spectra of FORZA graphene before and after heat treatment up to 1700 ˚C. For certain applications, the neat Forza graphene is more suitable for entering various material matrices, while other applications can benefit from the properties of the annealed graphene

Figure 5: Distribution of Raman peak parameters and peak relations for a Raman map of FORZA graphene

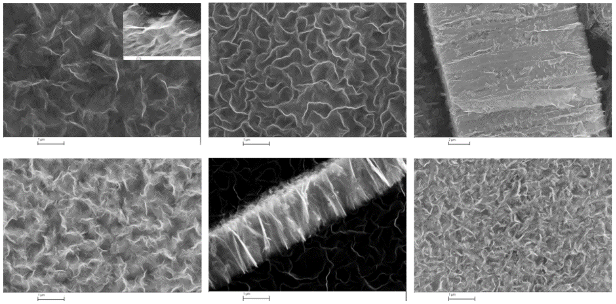

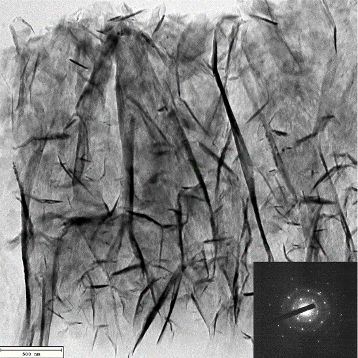

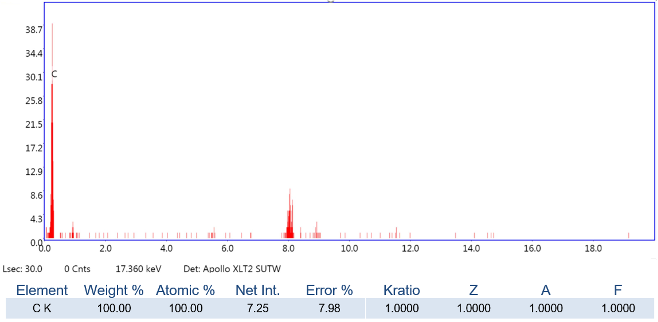

Figure 6 shows some of the morphologies obtained as shown by SEM. Using TEM, and subsequent electron diffraction shows that the graphene obtained from the FORZA reactor is of high crystallinity and quality (See Figure 7) with no impurity found (Figure 8 ).

Figure 6: SEM images from the graphene morphologies that arise from varying production parameters in the FORZA reactor. By tuning gas compositions, temperatures and plasma power, different morphologies are grown. Here are shown wavy walls, maze-like walls, dense structures, highly branched, and loose branched morphologies (scale bars = 1 μm)

Figure 7: TEM image of a FORZA graphene flake. The inset at the bottom right shows the corresponding electron diffraction peaks from an arbitrary position in the TEM image. The diffraction pattern shows that the graphene has a high degree of crystallinity (scale = 500 nm)

Figure 8: EDS spectrum of FORZA graphene. EDS indicates that the graphene contains only carbon without any impurity found (The peak at 8.0 keV refers to copper in the sample holder)

3.2 Implementation of FORZA graphene in materials for applications

The FORZA graphene has been successfully integrated in various polymer matrices, either as produced or annealed or chemically functionalized, as well as mixed with other available graphene-like materials. Some of the applications are of both military and civil interest. In addition to producing graphene in powder form, it can also be deposited directly on large surface areas of various materials. The only limit to direct deposition with the PECVD methodology is for the host material to sustain the conditions, such as temperature and low-pressure growth conditions.

3.2.1 Graphene enhanced poly lactic acid polymer (PLA), epoxy, vinyl esters, and elastomers

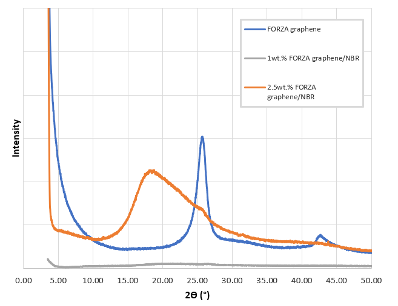

The dispersion of graphene is one of the main challenges for graphene composite applications. CealTech has successfully developed methods to homogeneously disperse FORZA graphene in various material matrices. XRD of one of the samples where graphene is fully exfoliated and homogeneously dispersed in nitrile rubber (NBR) is showed in Figure 9. In addition to expected changes in strength of the composite materials, the fatigue performance is expected to be enhanced. Confirming this is part of ongoing research programmes. Significant improvement in these properties, will facilitate early commercialization of various applications of low wt% graphene composites.

In order to improve electrical conductivity as well as terahertz absorption of epoxy composites, FORZA graphene has been homogeneously dispersed in epoxy at various concentrations. Van Rheenen et al.[11] have tested these materials and found that introducing as little as 0.1% graphene in epoxy increased the electrical conductivity by a factor 108 which was further improved by increasing the graphene concentration. The implication is that using graphene enhanced materials as coatings has many possible practical applications due to e.g. making insulating materials electrically conductive. The capability of enhancing microwave and near infrared absorption makes the material interesting for among others stealth applications.

Figure 9: XRD patterns of FORZA graphene and FORZA graphene enhanced NBR. The XRD pattern of FORZA graphene exhibits a characteristic diffraction peak at 2𝜽 = 26,268° (d = 0.339 nm), which is assigned to the (002) plane of graphene. The interlayer distance will be increased when graphene is intercalated by NBR molecules, leading to intensity decrease and a shift to lower angle or disappearance of this peak. This peak totally disappears in the sample containing only 1 wt.% FORZA graphene, indicating complete exfoliation of the graphene layers

3.2.2 Graphene enhanced fibre-reinforced polyester

Graphene was homogeneously dispersed in polyester resin via high shear rate mechanical mixing. The resin/graphene mixture was then well mixed with a hardener. Graphene enhanced glass fibre/polyester composites were prepared by hand-lay-up techniques, with 65 % polyester resin and 35 % fibreglass. The prepared resin was poured on a stainless-steel plate with the surface treated by wax. A piece of fibreglass mat was then placed on the resin mixture and additional resin was spread by brush on the mat. A steel roller was used to press air out of the sample to improve the wetting of the polyester resin in and on the fibreglass mat.

The strength properties of a matrix material modified with graphene changes as a function of the graphene concentrations. For polyester the tensile strength increases with increasing concentration of graphene, while the E-modulus and maximum flexure strength seem to go through a maximum value at concentrations below 0.1 wt% graphene (See Table 1). For each different matrix, these properties need to be investigated before concluding on suitable graphene concentrations

Table 3-1: Increased mechanical performance by introducing FORZA vertical graphene into fibre reinforced polyester

|

Samples |

Average Standard Tensile Strength |

Increase compared to Ref |

Average |

Increase compared to Ref |

Average Standard Maximum Flexure Stress |

Increase compared to Ref |

|

Polyester/fiberglass (Ref) |

100.6(9.6) |

- |

6598(687) |

- |

190(11) |

- |

|

0.01wt% FORZA Graphene |

114.9(3.0) |

14.2 |

7323(686) |

11.0 |

205(10) |

7.7 |

|

0.1wt% FORZA Graphene |

124.0(3.9) |

23.2 |

7129(441) |

8.1 |

200(7) |

4.8 |

3.2.3 Direct deposition on carbon fibres and other functional materials

Graphene coatings have numerous applications in areas of electronics, mechanical wear reduction, and mechanical strength. Perpendicular graphene is strongly light absorbing [12]. Perpendicular graphene coatings can also be combined with polymers and existing commercial carbon materials such as carbon fibres for improved strength.

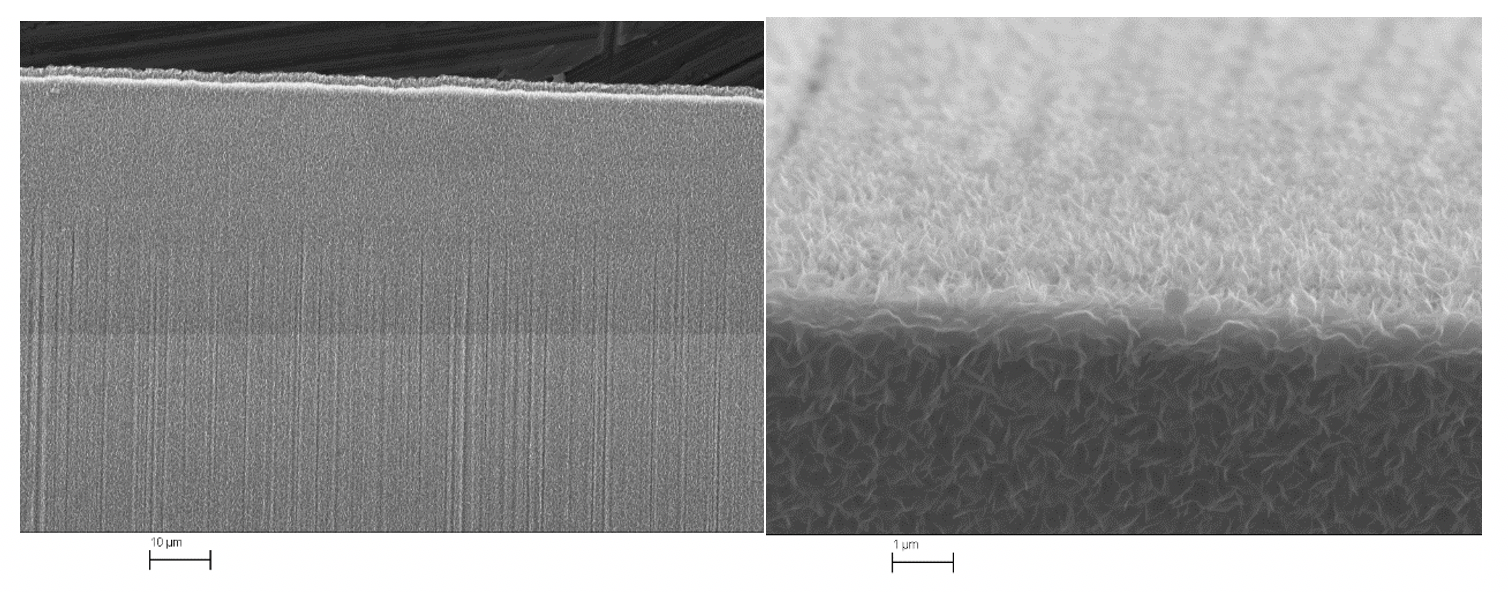

Figure 10: SEM images of direct deposition of FORZA graphene on a Cr-based knife edge. Left: low resolution side view of the blade, and right: higher resolution image of the edge

Various substrates, such as metals and ceramics and even organic materials, have been coated with graphene in the FORZA machine. The capability to directly grow and coat up to the 86 cm width of the plasma region makes it possible to produce a large area and uniform coating up to 6.7 m2 and could be utilized among others in large scale electronics. Figure 10 shows SEM images of graphene growth on a Cr-plated knife blade.

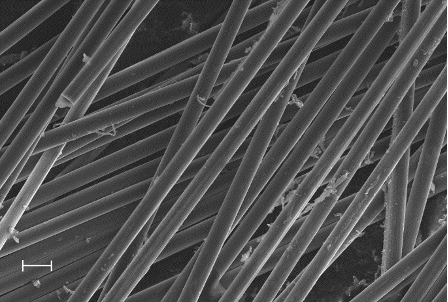

Yao Chi et. al. [13] reported that that the interface strength of composites and carbon fibres were considerably improved (by 173%) by growing graphene nano walls on carbon fibres. To confirm this using the FORZA machine, graphene was grown on carbon fibre bundles (see Figure 11), which is a topic for further investigation towards improving material strength.

Figure 11: SEM images of direct deposition of FORZA graphene on carbon fibre. Graphene is seen as the paler material that resides on the darker carbon fibres (scale = 10 μm)

3.3 Battery technology

Batteries are critical for both general society as well as the modern military, and the need for rapid charging may impair operations. The time needed to fully charge devices may be a critical factor. To study the possibility to enhance charging rate FORZA graphene has been incorporated into battery electrodes.

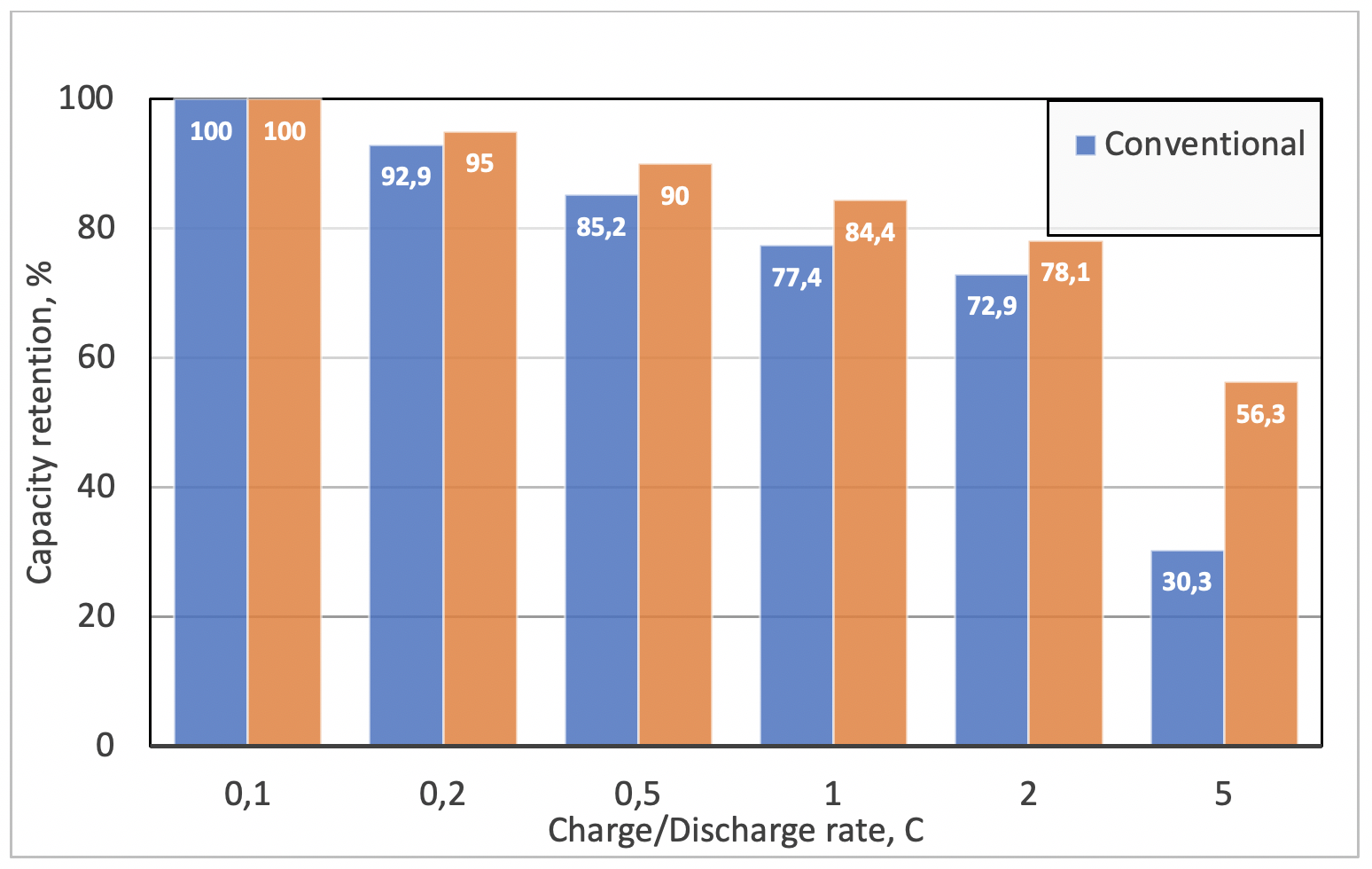

Figure 12: Advantage of electrodes which incorporate graphene for fast charging and discharging. Conventional electrode discharge capacity (represented as blue columns) drops more drastically than the electrode with graphene (represented as red columns) when the rate of discharge (discharge current) increases from 0.1C to 5C.

Lithium ion battery (LIB) performance includes the aspects of, for example, energy capacity, battery life and safety. The capacity of a LIB is related to the rate of discharge. LIB experiences increasing capacity drop as the discharge rate is increased. Graphene is highly effective in enhancing the capacity as discharge rate increases, which means shorter charging time and higher power output. This is due to higher electrical conductivity and improved ionic transport kinetics provided by graphene [14],[15]. A preliminary study was performed at CealTech (as shown in Figure 12 ) and demonstrated an improved rate capability of the cathode with graphene. Graphene also helps to increase battery life by mitigating instability of the electrode caused by volume expansion and irreversible phase transitions of the active material [14]. It is also reported that LIB safety can be improved because graphene can confine the growth of lithium dendrites which is a significant cause for shorting the LIB cell and may lead to fire and even explosion [16].

3.4 Other potential applications

Graphene-reinforced advanced materials are of military as well as civil importance, to e.g. reduce weight of various types of equipment by using stronger and still lightweight materials. In addition, the enhanced electrical and thermal conductivities of graphene enhanced host materials may be beneficial for smart clothes as well as in aiding anti-fouling and anti-icing properties of aviation machines.

An important area of interest is ballistic protection, and since graphene has been shown to be compatible with materials used as ballistic protection, there are projects ongoing that aim to show improvement of the relevant properties. Potential benefits obtained include increased ballistic performance and/or lighter personnel protection equipment and lighter protection for vehicles.

4.0 Conclusion

We have presented a machine for large scale production of high-quality graphene coatings and flakes. The machine is capable of continuous production of graphene flakes as well as coating areas as large as 6.7 m2. The graphene is found to be of excellent quality.

Dispersion of graphene in a host matrix is essential for successful composites, and CealTech’s FORZA graphene has been found to easily disperse in a variety of solvents, polymers, organic compounds, and oils. The FORZA graphene is well suited for composite and energy storage applications. We have explored graphene enhancement of fibre reinforced polymer materials, elastomers, and paints/coatings with regards to improving strength, electrical and thermal conductivity, mechanical and chemical resistance, anti-corrosion, and anti-icing. Perpendicular graphene is an excellent conductor with a high surface area. We have demonstrated direct deposition of graphene on various substrates, and in particular on metal foils for use as electrodes for batteries and supercapacitors. The application areas demonstrated are believed to be relevant for both civil and military use.

References

[1] Long Chen et al. Coatings (2017), 7, 158

[2] Abdul-Rahman O. Raji et al. ACS Appl. Mater. Interfaces (2016), 8, 5, 3551–3556

[3] Xiao Huang et al. Prog. Aerospace Sciences (2019), 105, 74-97.

[4] Claudia Backes et al., 2D Mater. (2020 ), 7, 022001

[5] Novoselov K S. et al., Proc. Natl Acad. Sci. (2005) 102 10451–3

[6] Md. Sajibul Alam Bhuyan et al., Int. Nano Lett. (2016), 6, 65–83

[7] Yi Zhang et al., Acc. Chem. Res. (2013), 46, 10, 2329–2339

[8] Nicolas Woehrl et al., AIP Advances (2014), 4, 047128

[9] D.A. Boyd et al., Nat. Commun. 6, 6620 (2015)

[10] Zhiqqiang et al., J. Phys. Chem. C (2011) 115, 5, 1422–1427

[11] Arthur D. van Rheenen et al., Nato paper, Trondheim, MP-AVT-304-15 (2019)

[12] Krivchenko, V. A., et al., Scientific eports 3 (2013) 3328

[13] Yao Chi et al., Appl. Phys. Lett. 108, 211601 (2016)

[14] K.H. Park et al., Nano Lett. 2014, 14, 4306-4313

[15] D.A.C. Brownson et al., Journal of Power Sources 196 (2011) 4873–4885

[16] J.A. Lochala. Small Methods 2017, 1700099.