Author(s): Steven Savage; Tom Thorvaldsen ![]()

DOI: 10.14339/STO-J-02-F3 | ISSN: TBD

Materials, and knowledge of their science and engineering applications, have facilitated human development since the Stone Age

Citation:

1.0 INTRODUCTION

The objective of The Journal of the Science & Technology Organization is trifold and extends beyond the traditional scope of the Organization. Firstly, the Journal will function as a medium for the dissemination of our work to the NATO STO contributing nations. Secondly, future editions of the Journal will include an outlook for the period to come and will review work the various panels have recently accomplished. Finally, but perhaps most importantly, it will serve as a peer- reviewed medium for publication of results from our Symposia, Specialists’ Meetings and Workshops.

In its peer-reviewed volumes, the Journal will serve as a forum and archive for excellent conference papers and will review the work the various panels and our Programme Committees have recently accomplished. By promoting scientific excellence in topics highly relevant for defense related research and development, NATO STO supports its stakeholders to stay at the forefront of S&T.

The NATO STO AVT Panel has been the pilot to adapt the peer review process to the NATO STO environment and use the opportunity the new journal format presents to highlight a recent activity – the Research Specialists’ Meeting

on ‘Graphene technologies and applications for defense.’ In total sixteen papers were presented during the Fall 2019 meeting in Trondheim, Norway. Of these five have been selected for publication, following peer review and based on scientific excellence and permission to publish. Hereinafter the military relevance and opportunities of novel graphene technologies are highlighted.

2.0 AVT-304: GRAPHENE TECHNOLOGIES AND APPLICATIONS FOR DEFENCE. A RESEARCH SPECIALISTS’ MEETING (RSM)

Materials, and knowledge of their science and engineering applications, have facilitated human development since the Stone Age. Materials for tools, for construction, and in particular for defense, which is the focus of this, the 2nd volume of the Journal of the NATO STO are as essential today as they were then. Materials of all types, from the simple to the complex, are growing in importance as societies around the world increase in sophistication, and credible attempts are made towards colonization of other planets. The issue at hand focusses on one (class of) material with expected impact and new possibilities for current and future use, namely graphene.

Graphene, a two-dimensional material built up of a symmetrical hexagonal lattice of carbon atoms, is one of the most attention-grabbing material discoveries of the 21st century. For both pure and applied scientists, technologies based on the extraordinary mechanical, optical, chemical, physical and electronic properties of graphene offer much to discuss. With potential uses ranging from corrosion protection on ships to high performance rubber tires, and from multifunctional aerospace composites to energetic materials and solid propellants, there is a clear potential for a wide range of applications in defense materiel.

Exploring this potential was the objective of the Research Specialists’ Meeting AVT-304 – Graphene Technologies and Applications for Defence held during the 44th AVT Panel Business Meeting. This issue includes selected and peer- reviewed papers from this 2-day meeting. They represent a small cross section of graphene technologies and what was presented during AVT-304 but serve well to illustrate the diversity and the trends in research towards defense applications of graphene- based technologies.

3.1 FACTS ABOUT GRAPHENE AND OTHER 2-D MATERIALS

3.2 Graphene – The Material with Extraordinary Properties

The foundation stone for the current interest in graphene was laid when Novoselov, Geim, and co-workers published their seminal paper on the extraordinary electronic properties of graphene in 2004 [1]. For this work they were awarded the Nobel Prize in Physics only six years later. This was not however the first report about the material we now call graphene, and it is clear that the intrinsic lamellar structure of graphite oxide, a precursor used in the production of graphene today was known as long ago as 1859 [2]. A theoretical study of graphene and its electronic properties was in fact published as long ago as 1947 [3] and the term graphene was introduced by Boehm and co-workers in 1986 [4]. However, recognition of the unique combination of properties offered by graphene only became widespread during the first decade of the 21st century, since when scientific and commercial interest in this material and other materials with similar lamellar structures has grown enormously.

The electronic, optical, chemical, thermal and mechanical properties of pure graphene are now well-known. Some typical properties are given in Table 1 below.

Table 1. Brief Comparison of Graphene Properties and Other Materials.

|

Property |

Graphene |

Comparison material |

|

Density |

2.27 g/cm3 |

7.75 – 8.05 g/cm3 (steel) |

|

Young’s modulus |

1034 GPa |

200 GPa (steel) |

|

Yield strength |

45±7 GPa |

250 MPa (steel) |

|

Ultimate tensile strength |

130 GPa |

400 – 550 MPa (steel) |

|

Failure strain |

20 % |

2 % (carbon fiber) |

|

Thermal conductivity |

2000 – 4000 Wm-1K-1 |

2200 – 3300 Wm-1K-1 (diamond) |

|

Electron mobility |

40 000 cm2 V-1s-1 |

1400 cm2 V-1s-1 (silicon) |

|

Optical transparency |

97.7 % @ 350 nm-2 mm |

Material dependent |

|

Permeability |

Impermeable |

Material dependent |

|

Chemical stability |

Stable in acid, alkali, organic solvents |

Material dependent |

|

Specific surface area |

2630 m2g-1 |

100–1000 m2g-1 (carbon nanotubes) |

|

Bandgap |

0 |

1.14 eV (silicon) |

|

Magnetism |

Non-magnetic |

Material dependent |

|

Melting temperature |

4000°C (sublimes) |

3422°C |

While the individual properties of graphene are extreme compared to other materials, this is not in itself sufficient for most practical applications. It is very rare for any material to be selected for an application based on only one property. Compromises must be made, between strength, corrosion resistance, toughness, conductivity, availability, cost, etc. What makes graphene attractive for practical applications is its unique "all round" combination of several extreme properties.

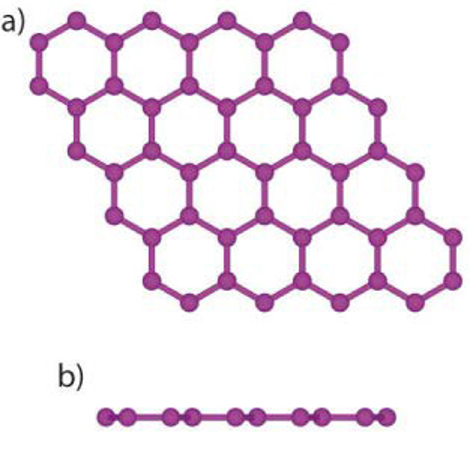

The extraordinary properties of graphene arise from its atomic structure, shown schematically in Figure 1.

Figure 1: Illustration of a Graphene Sheet Seen from Above (a) and from the Side (b). [Copyright: L.H. Karlsson. Reprinted with permission.]

The graphene structure is a perfectly symmetrical 2-dimensional (2-D) arrangement of carbon atoms in a hexagonal lattice, which is only one atom thick. Each carbon-carbon bond is equal, and in pure graphene there are no defects to disturb the local atomic environment. However, pure graphene can only be produced under laboratory conditions, and for practical applications graphene will always contain imperfections and impurities, depending on the production method.

Controlling the level of defects and impurities is one of the major challenges yet to be overcome, although high quality graphene can today be produced in quantities of hundreds of kilograms.

The properties of graphene can also be modified by attaching various chemical groups to the surface and edges. In this way, graphene can be made more compatible with other materials, which is especially relevant for the production and mechanical properties of graphene-polymer composites. Graphene can also be deliberately functionalized for use in chemical and biological sensors.

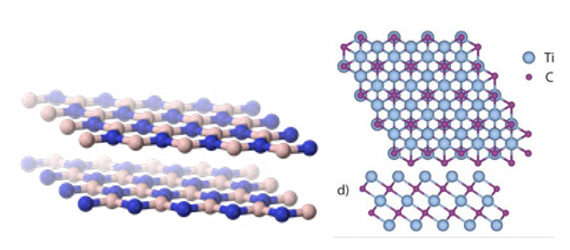

Figure 2: (Left) Illustration of Two-Dimensional Hexagonal Boron Nitride. Boron is Represented by the Blue Dots and Nitrogen by the Pink. [Copyright: Benjah-Bmm27]2 (Right) Illustration of the MXene Ti3C2 [Copyright: L.H. Karlsson. Reprinted with Permission].

Beginning from an exploratory team (AVT- ET-161 – Graphene technologies: a preliminary assessment of the military potential) back in 2016, eight nations (Bulgaria, Finland, Germany, United Kingdom, Norway, Sweden, Turkey, United States) thereafter formed a team of materials specialists in 2017 which planned and conducted the AVT-304 RSM.

Since the beginning of the 21st century enormous strides have been made in Materials Science and Engineering (MSE). Following the end of the Cold War a paradigm shift has taken place in MSE. When geopolitical tensions

3.2 Other Two-Dimensional (2-D) Materials

The lamellar structure of graphene is well- known, and inspired by the extreme properties being discovered, scientists began to explore other materials with similar structures. It was soon found that a large number of other two- dimensional materials with equally interesting, but different properties, exist. While these are structurally more complex than graphene, as shown in Figure 2, their different atomic compositions result in a wider variety of, in particular, electronic properties than does graphene. Today a whole new class of 2-D materials is being studied.

4.0 BACKGROUND TO THE AVT-304 RSM

4.1 Introduction/Background

Beginning from an exploratory team (AVTET- 161 – Graphene technologies: a preliminary assessment of the military potential) back in 2016, eight nations (Bulgaria, Finland, Germany, United Kingdom, Norway, Sweden, Turkey, United States) thereafter formed a team of materials specialists in 2017 which planned and conducted the AVT-304 RSM.

Since the beginning of the 21st century enormous strides have been made in Materials Science and Engineering (MSE). Following the end of the Cold War a paradigm shift has taken place in MSE. When geopolitical tensions relaxed and concomitantly defense budgets began to shrink, cutting-edge research into materials shifted from being defense-needs driven towards meeting broader societal needs for energy efficient transport, information technology, miniaturization, mobility, environmental sustainability and healthcare. As a result, the range of materials available and knowledge of their properties is vastly greater today than at any previous time in history. Although developed for civil applications, these materials are available worldwide for defense purposes. It should be noted that the vast majority of materials are dual-use, with similar defense and civil applications.

Much defense materiel in service today was built using materials developed 50 or more years ago, before the advent of graphene, additive manufacturing, electric propulsion, adaptive camouflage, high performance sensors and many of the other advanced technologies now available. As we discuss the next generation of aerospace, ground, space and marine platforms, we cannot ignore new and emerging materials currently in the "pipeline." This is not to say that existing materials have outlived their role. In many cases it is possible, and indeed likely, that existing materials, perhaps manufactured using improved methods, will continue to be important in platforms of the future. However, it is also likely that new materials, such as graphene, will give rise to new technologies and new applications. It is imperative that we evaluate and assess their strengths and weaknesses, manufacturing, availability, cost and environmental impact and their potential applications.

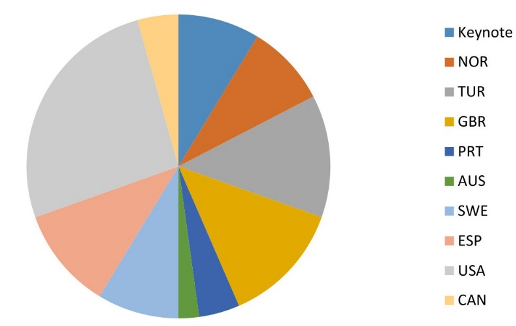

During the RSM, sixteen oral presentations, including two keynote lectures, and six posters were presented and displayed by scientists from nine nations (Figure 3) during this two-day meeting, which concluded with a presentation by the Technical Evaluator and a lively discussion on the way forward.

Figure 3: The National Distribution of Authors Contributing to AVT-304 RSM.

The majority of presentations were concerned with graphene technologies and their potential defense applications. However, defense organizations are often reluctant to implement new, and unquestionably high-risk technologies, so the majority of research and development on graphene has therefore been financed by public and private investment, resulting in a growing number of civilian products.

To obtain a balanced overview and to place graphene in a broader context, a keynote presentation describing the Graphene Flagship3 and in particular development of roadmaps was included in the RSM. A superficial roadmap of civil applications, many of which are dual-use, is given in Figure 4.

Figure 4: A Broad Roadmap Covering Civil Applications for Graphene, Many of Which Are Dual-Use. [Copyright https://graphene-flagship.eu/SiteCollecionImages/News/2018/Roadmap.png.

4.2 Applications Considered in AVT-304

The range of potential applications for graphene and related technologies is enormous. Space allows for only a few examples to be mentioned here, but the list below includes all the applications discussed during the AVT-304 RSM:

- • Corrosion protection;

- • Thermal management;

- • Resin-transfer composites;

- • Ballistic protection;

- • Rocket motor insulants;

- • Bearings and tribology;

- • Energetic materials;

- • Electro-optical, mechanical, and chemical sensors;

- • Stealth technology; and• Structural composites for aerospace.

Pure graphene, as an extremely thin 2-D layer is difficult to use alone. It is also difficult to manufacture in large quantities, although roll to-roll production (as presented by Fisher [5])is maturing. Graphene shows broadband optical transparency and excellent electrical conductivity, which suggests applications as a transparent electrode in displays, for signal readout and various electro-optical sensors. Charipar et al.report in their paper [6] show how graphene can be combined with zinc oxide, a well-known optically sensitive detector material to produce a solar-blind sensor to detect the ultra violet signature of a missile launch. Electronic applications, where the excellent electrical conductivity is beneficial are also possible, and a prototype broadband VIS-SWIR has recently been marketed. However, because graphene lacks a natural bandgap other 2D materials may be more suitable for some electronic applications due to their inherent bandgaps. Graphene is extremely impervious even to small molecules such as gases and water vapor, suggesting applications which depend on barrier properties. It is impractical to use pure graphene in these applications, but this material can be used to enhance the properties of various types of coatings and membranes,e.g., corrosion protection and personal protection in gloves and clothing. There are other, less obvious, but nonetheless attractive applications, which benefit from impermeability. Polymers are relatively porous and easily absorb organic solvents and water, which leads to dimensional changes and changes in mechanical properties. This is a well known problem with carbon fiber composites. Reducing the absorption rate and amount of absorbed solvent/water can lead to improved dimensional stability and reduced degradation of mechanical properties of composites in hot and humid environments.

Composites are invaluable in modern defense materiel, from structural composites in aerospace, surface vessels and ballistic protection to functional composites in rubber products, such as tires and seals, and in self-lubricating bearings. Fiber- reinforced composites, while having excellent mechanical properties in two dimensions frequently suffer from poor interlaminar fracture toughness, and poor electrical and thermal conductivity. All these parameters can be improved by the addition of small quantities of graphene flakes to the resin matrix, resulting in improved impact tolerance, reduced sensitivity to lightning strike and improved thermal conductivity. Graphene composites show important potential for aerospace applications, and they are being studied by all the major aerospace companies. Robles et al. [7] discussed the production of graphene-enhanced fiber composites by resin- transfer molding and showed that Young’s modulus was improved, but at the expense of tensile strength. Okan et al. [8] showed that functionalizing graphene with oxygen functional groups was successful in improving the mechanical properties of the graphene- resin interface in fiber composites. Graphene may also be combined with bio-based fibrous composites, as presented by Abreu et al. [9], who showed interesting antibacterial properties and improved electromagnetic shielding properties of these composites. The terahertz spectrum is growing in importance in several areas of sensor technologies, and the terahertz absorption of graphene-epoxy composites was presented by van Rheenen and co-workers [10]

Thermal management is a growing problem in aerospace, where the power of electronic components is increasing while the space available for heat dissipation is decreasing. The high thermal conductivity of graphene can be useful in thermal management, as shown by Caylan et al. [11].

Ballistic protection systems are of course specific defense applications, and the mechanical properties of graphene are undoubtedly attractive to study in this application. However, strength alone is not sufficient, and the application is fraught with difficulty. A brief review by Savage [12] and preliminary studies by Gago et al. [13] suggest there is some potential, but much work remains before it can be established if there is a practical potential for graphene in ballistic protection.

4.3 Selected Papers from AVT-304

Five papers from AVT-304, each describing original research, have been selected for publication in this issue. These papers were selected on the basis of:

1. Scientific quality;

2. Clear relevance for defense; and

3. Cleared for public release.

A single-blind peer review was performed. These papers represent a small cross-section of what was presented during AVT-304, but serve well to give examples of graphene technology and trends towards defense applications. Many applications for graphene technologies are dual-use, and in these cases it is not motivated for defense organizations to invest heavily in research during their early development. It is however important to monitor their progress and evaluate their defense relevance. However, some applications are clearly defense oriented. These include a range of electro-optic sensors, ballistic protection, high performance structural materials, functional materials for warheads, and energetic materials. Papers on all these topics were presented at the RSM, and with the exception of ballistic protection, examples are included in this issue. Ballistic protection is excluded because of the complexity of the materials requirements and current lack of knowledge regarding graphene in this application.

In addition to the papers published here, two invited keynote papers were presented. The first, by Reiss [14] gave an excellent overview of the road-mapping activities of the Graphene Flagship, and the second, by Selegård [15] gave an introduction to the potential for multifunctional applications of graphene in aerospace. Although the focus of AVT-304 was on graphene technologies, a general introduction to related 2-D materials was given by Karlsson [16].

An essential aspect of the RSM was an independent evaluation of the work presented. The report by Dryfe [17] was presented at the end of the RSM and was followed by a lively discussion. In line with the applied nature of the work presented in the RSM, an analysis of graphene technologies following the DOTMLPFI methodology was also performed. This analysis is given in the appendix at the end of this introduction.

Production of graphene in sufficient quantities, of the appropriate quality and at an affordable cost is a prerequisite to any practical application, be it in batteries for energy storage, energetic materials or structural composites. Beukes et al. [18] report studies of a novel, plasma enhanced chemical vapor deposition process and the graphene flakes and coatings which can be produced by the FORZA process. While this is still some way from being an established production method, it is clearly an important step beyond laboratory-scale experiments. Other presenters also considered production and processing challenges, including high shear-rate methods to incorporate graphene homogeneously in a polymer matrix for structural composites and mechanical milling for self-lubricating graphene-polymer composites for wear- resistance bearings.

Polymer composites are used extensively in many defense applications, particularly those needing a combination of properties including high stiffness and strength, impact resistance, electrical and thermal conductivity. Polymer composites modified by the addition of graphene offer a wide range of properties, which, depending on the polymer and the graphene addition, can be tailored for a specific application.

However, incorporating graphene into a polymer is far from simple, especially on the industrial scale. Many processes which work satisfactorily on the laboratory scale are simply not suitable for industrialization. Lynch [19] describes a novel, high shear-rate melt-processing method starting from mined graphite, which requires minimum pre-processing. The process appears to be scalable, and it demonstrates its applicability for composite production using several high performance polymers. The composite produced was combined with a novel electroplated metal-foil coating. The plated graphene polymer composites showed a number of improved properties, although it is clear there is potential for further improvement through optimization of the process.

Energetic materials are essential components of many weapons systems, warheads and propellants. Depending on the application, it is necessary to tailor, and/or maximize the energy content or release rate of the material during burning or detonation. Aluminum is frequently added to energetic compositions to increase the energy content but using aluminum in its optimal form as nanopowders suffers from reduced burn rate due to the relatively thick oxide layer which forms. This reduces the energy content and the release rate. By protecting the nanopowders with graphene oxide it is possible to reduce the formation of the aluminum oxide, and simultaneously add (through the graphene oxide) additional oxygen to the composition. A number of literature reports indicate improvements obtained include burn rate, thermal stability, and energy release, combined with reduced sensitivity for electrostatic discharge, impact and shockwave. Gottfried [20] has used a novel analytical method: Laser-Induced Air Shock from Energetic Materials (LASEM) for high resolution, laboratory-scale studies of the detonation of trinitrotoluene (TNT) with additions of different sizes of aluminum powders, and with and without coatings ofgraphene oxide. Significantly enhanced energy release rates were observed for the aluminum nanopowders coated with graphene oxide.

Although these results are promising, the need for further study of the effects of impurities was highlighted.

Continuing on the theme of warheads, Torry and Whittaker [21] propose the use of graphene to improve the performance of an inert component, that is, the insulant between the solid-fuel propellant and the wall of the combustion chamber in a rocket motor. Filled elastomer composites are frequently used, which can lead to problems if the propellant (or more specifically low molecular weight components such as plasticizers of the propellant) diffuse into the insulant. This leads to degradation of the propellant. Graphene is well-known to be impermeable and to provide an excellent diffusion barrier, in addition to possibly improving mechanical properties of the insulant. Tests on a graphene-modified insulant showed that diffusion of dioctyl adipate, a commonly used binder in solid propellants into the insulant, was significantly reduced. This suggests a route to extending the usable lifetime of the rocket motor. The graphene-modified insulant may also enhance the mechanical and thermal performance of the insulant. This may provide additional benefit because hot gases from burning propellant, leaking through the insulant can also degrade / severely damage the rocket motor casing and other components of the rocket motor during flight, which can lead to total failure of the missile system.

Electro-optic sensors are essential for modern information gathering. Fundamental to the sensor is the detector, where incoming information carriers in the form of photons of different wavelengths are converted to electrical signals. Ultraviolet sensors are of increasing interest because they can be used for missile launch detection, and there is an atmospheric window which can be used. Thedetector needs a transparent (to the photons of interest) and electrically conductive electrode.

Graphene, with its broadband transparency and extraordinary electrical conductivity is an obvious candidate, which is compatible with the zinc oxide photodiode detectors. Graphene’s excellent flexibility also opens for the possibility of making non-planar conformal arrays, which is not possible using conventional detector materials. The potential for ultraviolet detectors with ultrafast response times combined with high sensitivity has been explored by Charipar et al. [6].

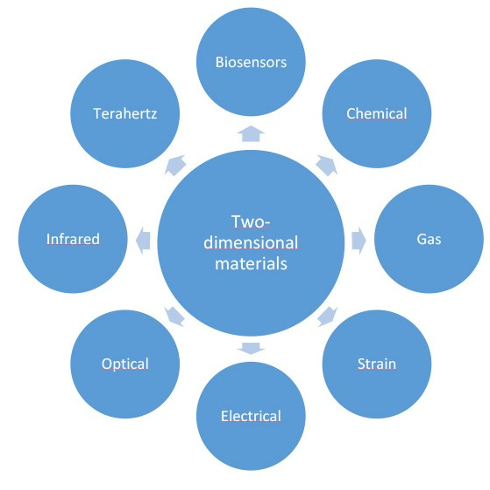

Figure 5: Various Sensors Possible Using Graphene and Other Two-Dimensional Materials. [Copyright L.H. Karlsson, 2019 and used with permission].

It was noted that while graphene alone is not an ideal photodetector, graphene/zinc oxide in combination offer high responsivity, high detectivity and fast response.

Graphene offers many other opportunities for sensor applications, which take advantage of the lightweight, large surface area, broadband absorption and chemical sensitivity with electrical readout using graphene. Karlsson [16] gave a broad overview of the sensor applications for graphene and related 2D materials, summarized in Figure 5, and Lam [22] et al. discussed the broadband applications of graphene sensors, from shortwave ultraviolet to longwave infrared. Lock [23], described a graphene-based chemical sensor to detect sulfur contamination in logistic fuel for fuel cells. This sensor has reached a TRL of 7 – 8.

5.0 SUMMARY AND THE WAY FORWARD

The field of graphene technologies is very dynamic. During the three years of the

needs, and to fund research and development in those essential applications where there are no dual-use drivers. These are typically ballistic and chemical protection, signature management, sensor technologies, weapons systems and their components including energetic materials Advantage to the defense scientist since it means that much research and development does not need to be funded from defense budgets. However, it is essential that defense organizations intensify efforts to monitor and evaluate new results against defense needs, and to fund research and development in those essential applications where there are no dual-use drivers. These are typically ballistic and chemical protection, signature management, sensor technologies, weapons systems and their components including energetic materials

It is therefore pleasing to note that the AVT Panel recently (May 2020) approved a new exploratory activity – AVT-ET-213 on The Military value of graphene technologies – to continue to evaluate graphene technologies, with a remit to focus on electro-optical sensors, propulsion, structural composites and protective coatings including signature management. This activity will continue until the Fall 2021 and will consider proposing follow-on activities in the AVT Panel.

The complete program of presentations and posters from AVT-304 is available from Science Connect. Some papers may require login.

6.0 ACKNOWLEDGEMENTS

The valuable work of materials specialists from nations which contributed to AVT-304, and in particular of the Technical Evaluator, is gratefully acknowledged. These nations are Sweden and Norway (co chairs), Bulgaria, Finland, Germany, Turkey, United Kingdom and United States. Without the excellent work of the scientists who performed peer review of the papers this issue of The Journal of the Science & Technology Organization would not have been possible.

7.0 REFERENCES

[1] Novoselov, K.S., Geim, A.K., Morozov, S.V., Jiang, D., Zhang, Y., Dubonos, S.V., Grigorieva, I.V., Firsov, A.A. Electric field effect in atomically thin carbon films. Science 306(5696):666-669, 2004.

[2] Brodie, B.C. On the atomic weight of graphite. Trans. R. Soc. 149:249-259, 1859.

[3] Wallace, P.R. The band theory of graphite. Phys. Rev. 71(9):622-634 ,1947.

[4] Boehm, H.P., Setton, R. and Stumpp, E. Nomenclature and terminology of graphite intercalation compounds. Carbon 24(2):241- 245, 1986.

[5] Fisher, T.S. Roll-to-roll plasma chemical vapor deposition for scalable graphene production and electro-mechanical applications. AVT-304, October 2019.

[6] Charipar, N.A. et al. Applications of graphene as a transparent conductor. AVT-304, October 2019.

[7] Barroeta Robles, J. et al. Resin Transfer moulding processing and properties of graphene-enhanced glass fiber laminate composite. AVT-304, October 2019.

[8] Okan, B.S. et al. Design and manufacturing of high performance graphene and carbon fiber reinforced hybrid nanocomposites. AVT-304, October 2019.

[9] Abreu, I. et al. Versatile graphene-based fibrous systems for military applications. AVT-304, October 2019.

[10] van Rheenen, A.D. et al. Transmission of terahertz waves through graphene/ epoxy samples – Correlation with electrical conductivity. AVT-304, October 2019.

[11] Caylan, O.R. et al. Graphene/copper heterostructures for thermal management. AVT-304, October 2019.

[12] Savage, S.J. Graphene for ballistic protection. Swedish Defence Research Agency FOI-R-4639-SE, October 2018.

[13] Gago, I. et al. Graphene-SiC Nanocomposites for new body armour systems. AVT-304, October 2019.

[14] Reiss, T. The graphene technology and innovation roadmap. AVT-304, October 2019.

[15] Selegård, L. Graphene, enabling compact and efficient aircrafts through multifunctionality. AVT-304, October 2019

[16] Karlsson, L.H. Novel two-dimensional materials for sensor applications. AVT-304, October 2019.

[17] Dryfe, R.A.W. AVT-304 specialists’ meeting on graphene technologies and applications for defense: technical evaluation report. AVT-304, October 2019.

[18] Beukes, J.A. et al. Plasma enhanced chemical vapor deposition reactor for large- scale production of high quality graphene. AVT-304, October 2019.

[19] Lynch, J. High performance, lightweight graphene enhanced polymer matrix composites for defense applications. AVT-304, October 2019.

[20] Gottfried, J.L. et al. Measuring the fast and slow energy release of laser-excited Al/GO composites. AVT-304, October 2019.

[21] Torry, S. and Whittaker, J. Graphene barrier coatings for solid rocket propellant insulants. AVT-304, October 2019.

[22] Lam, S.Y. and Pedlar, I. Graphene sensors for defense applications. AVT-304, October 2019.

[23] Lock, E. Novel graphene functionalization approach leading to ultrasensitive, robust and fast sulfur contaminants detection in aviation fuels. AVT-304, October 2019.

APPENDIX

An analysis of the potential impact of graphene on defense capabilities, using the DOTMLPFI scheme.

DOTMLPF is defined in the Joint Capabilities Integration and Development System of the U.S. DoD and used to define acquisition requirements and evaluation criteria for future defence programs. As such it is a suitable tool to analyze the potential impact of graphene technologies on future defence capabilities. NATO uses a similar tool with the addition of Interoperability, to take into account the additional requirements of a multilateral force. The U.K. MoD uses a similar tool with the acronym TEPID-OIL. A more recent implementation of DOTMLPF also includes Policy, i.e., DOTMLPF-P. In this analysis we used the NATO implementation of the tool.

D: Doctrine

It is unlikely that the use of graphene technologies will have an immediate effect on military doctrine unless graphene enables a completely new and to date unavailable technology which could be implemented in new materiel. A new or much improved camouflage or weapon system might have an impact on doctrine

O: Organization

It is unlikely that the use of graphene technologies will have an immediate effect on military organization, unless improvements in materiel are so profound as to affect, e.g., the numbers of personnel needed for a mission.

T: Training

It is unlikely that the use of graphene technologies will have an immediate effect on training of military personnel unless improvements in materiel are so profound that mission profiles, e.g., the use of a new and effective

M: Materiel

It is highly likely that the use of graphene technologies will affect the performance of defence materiel, in ways that are difficult to foresee. See below for a more detailed analysis

L: Leadership

It is unlikely that the use of graphene technologies will have an immediate effect on military leadership.

P: Personnel

It is unlikely that the use of graphene technologies will have an immediate effect on military personnel.

F: Facilities

It is highly likely that the use of graphene technologies will have an effect on military facilities. See below for a more detailed analysis.

I: Interoperability

It is unlikely that graphene technologies will have an immediate effect on interoperability between NATO forces.

Detailed Analysis

Materiel

Implementing graphene technologies into defence materiel to improve performance and/or economy is the raison d’être for this study, and it is certain that many aspects of military materiel will be affected. Design and manufacturing must be adapted to take account of new properties and property combinations, and maintenance procedures and schedules will be affected. Repair processes will also be affected. To take one example, if graphene-based technology isused as lightning protection on airplanes the repair process after a lightning strike may be simplified. If a graphene-based sensor is used then that sensor will have properties unlike existing sensors and must be maintained ina different way. Supply chains will need to be updated as graphene technologies do not appear in existing chains, and suppliers willneed to adapt. Possibly new suppliers will need to be found, and new certification procedures must be developed, e.g., if graphene-based energy storage (batteries) are implementedin materiel. This latter application seems quite likely within the near term although not in large volumes.

Facilities

To a lesser extent facilities will also be affected by the use of graphene technologies, especially repair and maintenance resources. New safety routines will need to be developed, and perhaps new or modified storage conditions will be needed. Since graphene technologies are expected to increase the robustness of materiel, it is expected that the requirements for storage facilities can be relaxed. However, for maintenance and repair it is possible that new tools may be needed.